What is sterilization of soft packaging?

Date:

2022-06-23

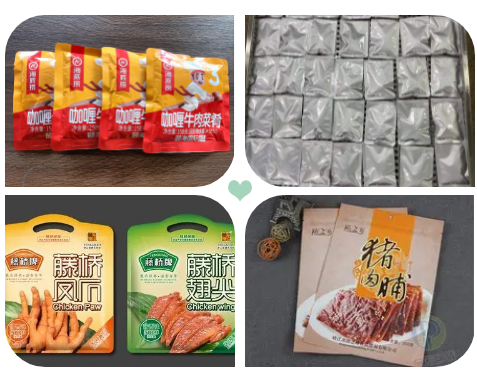

Soft packaging products refer to containers made from soft materials such as high barrier plastic films or metal foils, as well as their composite films, formed into bag-like or other shapes.

Soft packaging products refer to containers made of soft materials such as high-barrier plastic films or metal foils, as well as their composite films, formed into bags or other shapes. After filling and processing the products, they are sealed by heat fusion and sterilized by heating (or pressurization), achieving commercial sterility, and can be stored at room temperature. The processing principles and methods are similar to those of canned foods. Common packaging containers include plastic cups, plastic bottles, cooking bags, and boxes.

Due to the particularly small allowable critical pressure difference of soft packaging materials, the internal pressure of the container can easily rupture as the temperature rises during the sterilization process. The characteristic of cooking bags is that they are resistant to pressure but not to expansion; while plastic cups and bottles are sensitive to both expansion and pressure. Therefore, reverse pressure sterilization technology is required during sterilization. This technology determines that sterilization equipment with separately controlled sterilization temperature and pressure must be selected during soft packaging production, such as full water type (water bath type), water spray type (top spray, side spray, full spray), steam type, etc., generally using PLC to automatically control various parameters.

It is important to emphasize that the four control elements of the sterilization process for metal cans (initial temperature, sterilization temperature, time, key factors) are also applicable to the control of sterilization for soft packaged foods. Additionally, the pressure during the sterilization and cooling processes must be strictly controlled.

Some companies use steam sterilization for soft packaging. To prevent cooking bags from rupturing, they simply introduce compressed air into the steam sterilization pot to apply reverse pressure to the packaging bags, which is a scientifically incorrect practice. This is because steam sterilization is conducted under pure steam conditions; if there is air in the pot, it will form an air pocket. This air mass moves around in the sterilization pot, creating cold zones or cold spots, leading to uneven sterilization temperatures and insufficient sterilization of some products. If compressed air must be added, a powerful fan needs to be equipped, and the power of this fan must be carefully designed to ensure that the compressed air is immediately forced to circulate by the high-power fan after entering the pot, allowing the air and steam to mix evenly, thus ensuring uniform temperature in the sterilization pot and ensuring the sterilization effect of the products.

Zhucheng lier Machinery Co., Ltd

Domestic excellent food, beverage, medicine and other fields of high temperature sterilization equipment, broken bag flotation drying line equipment suppliers and overall solution service providers.

Company Phone:

+86-182-6566-6762

National Service Hotline:

www.lretort.com

Company E-mail:

56313324@qq.com

Company Address:

Middle Section of High-tech Park Industrial Avenue, Mizhou Street, Zhucheng City

mobile phone station

Powered by 300.cn SEO Tags Privacy Policy